Description of our patented technology

The biomethanation process

Biomethanation is a natural process in which bacteria produce methane by breaking down organic matter in an anaerobic environment—i.e., in the absence of oxygen. This process occurs in three main phases: hydrolysis, acidogenesis, and methanogenesis. Each phase involves different types of micro-organisms that progressively decompose the organic matter into biogas, primarily methane. At Anatis, we specialize in optimizing this process for industrial applications.

Fluid-Anyole®, the ABR-type biomethanation

Anatis has developed the patented Fluid-Anyole buried tank system, inspired by the specific technology of ABR (Anaerobic Baffled Reactors) biomethanation. Thanks to its baffled design, this system allows for the targeted treatment of a wide range of effluents, from the simplest to the most complex. The technology is particularly well-suited for industrial liquid discharges, providing a robust and efficient solution. With this approach, industries can benefit from a more integrated treatment process and optimal energy recovery. More information about the design at the bottom of the page.

With Fluid-Anyole®, easily treat the most complex effluents

Thanks to its patented baffled biomethanation technology, the Fluid-Anyole® buried tank solution offers an automated and robust treatment capability for a wide range of organic effluents that are often difficult, if not impossible, to treat with other systems :

- Rinse Process Water (RPW)

- Fatty substances : Cheese whey, Brewery yeast, trub, production waste...

- Composites : sugars, chocolate, para-pharmaceuticals, slaughterhouse wastes, food tanker cleanings...

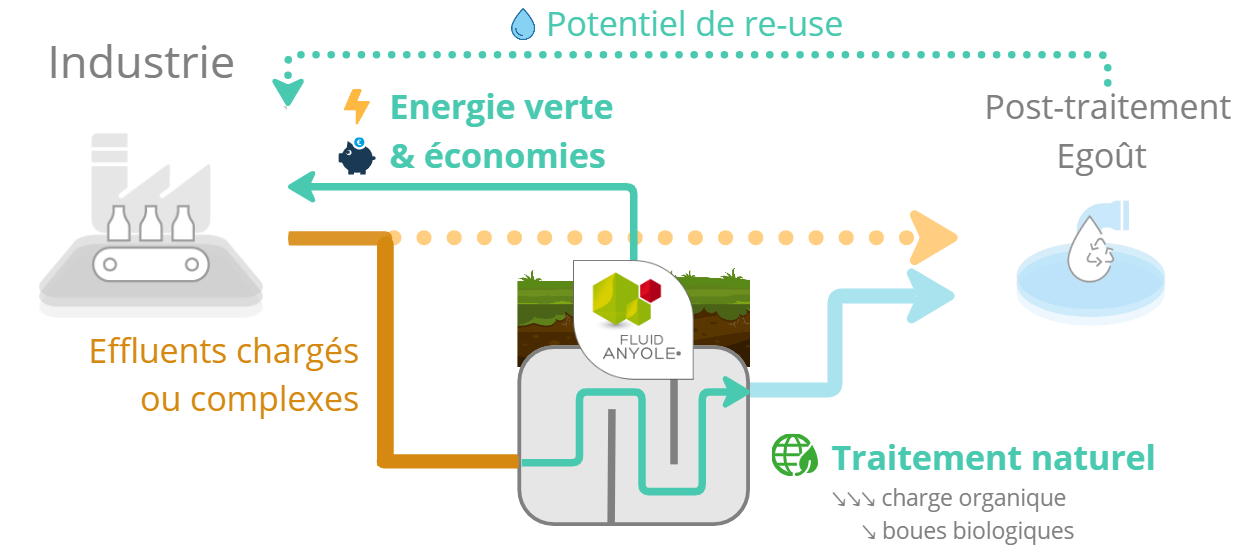

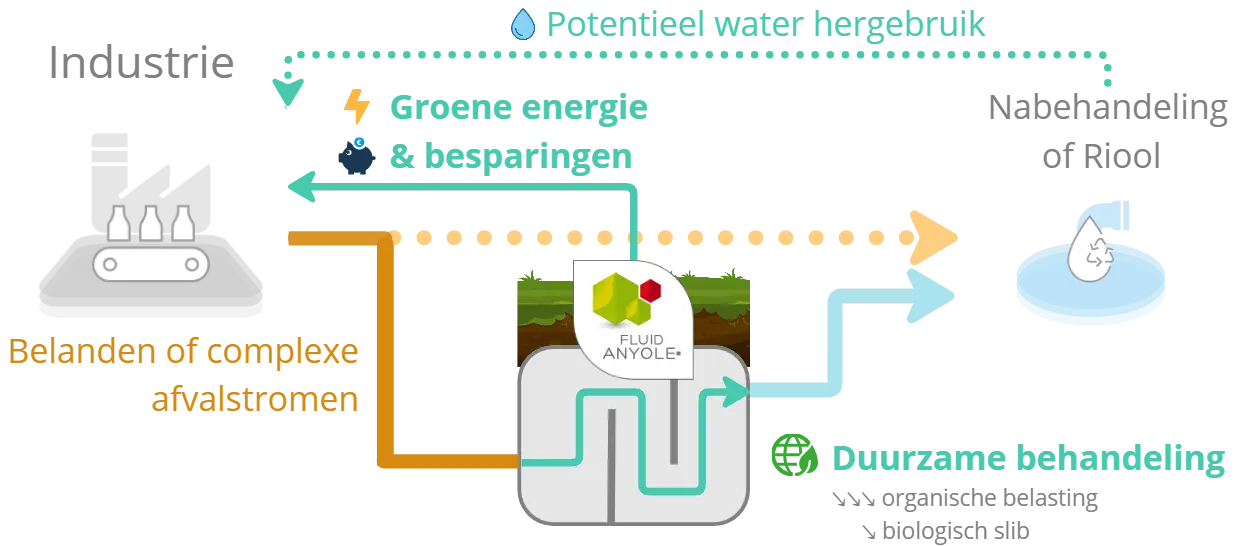

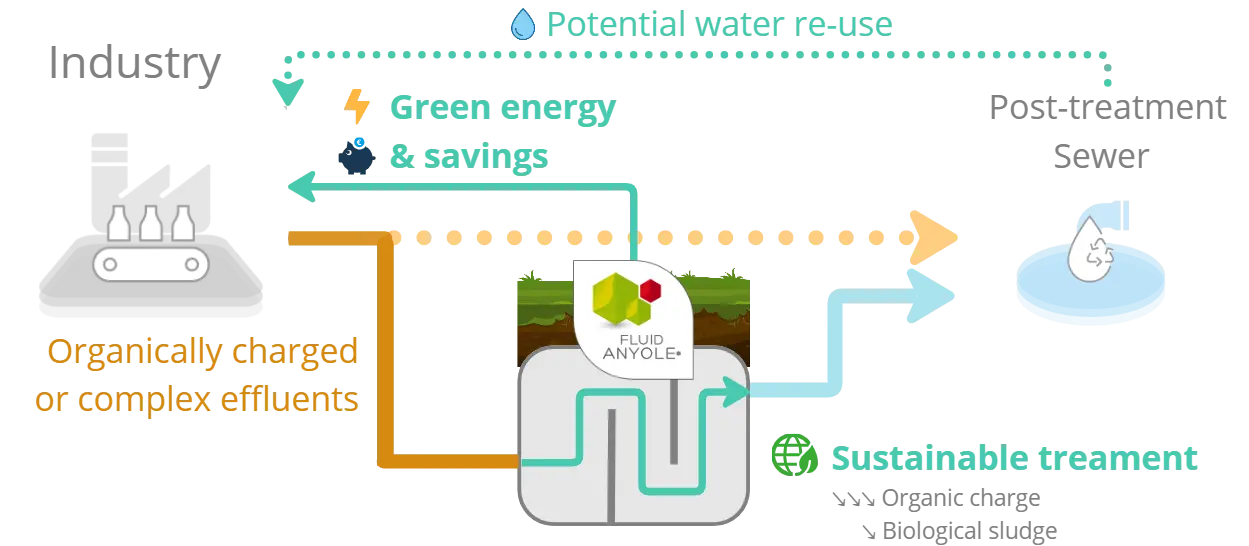

Integrating the system into your industry

Fluid-Anyole® is installed between the production output and the existing treatment system (e.g., grease separator, decanter, wastewater treatment plant) or the discharge to the sewer.

Natural Treatment of Your Diverse Effluents

Thanks to its unique ABR biomethanation technology, Fluid-Anyole® naturally reduces organic load by up to 90% and decreases the biological sludge typically produced by other systems by half.

Moreover, it can treat effluents such as raw water before entering a grease separator or decanter, production waste (such as cheese whey, brewery yeasts, sauces), and co-products from pharmaceutical manufacturing.

With Fluid-Anyole®, we focus on the most problematic aspects of your discharges, whether addressing the entirety or the "20% responsible for 80% of your issues.

Valorization and Savings for Your Industry = Return On Investment

Through the biogas produced and converted in our cogeneration or biogas boiler solutions, you gain a source of green electricity and heat for your industry. Moreover, with Fluid-Anyole®, the more organic load you valorize, the greater your production of renewable energy.

This valorization is complemented by significant savings that Fluid-Anyole® brings to your industry. For example, the substantial reduction in energy and product consumption in your existing treatment system, the ability to continue your development without expanding your treatment facilities, and the savings from outsourcing certain waste (such as sludge from grease separators and decanters, whey, yeasts, production waste, etc.).

All these elements contribute to a return on investment that is both financial and ecological.

What distinguishes Fluid-Anyole® ?

Fluid-Anyole® has been specifically designed for the treatment of industrial wastewater. Based on the natural biomethanation process, it consists of a range of modular baffled reactors (ABR type) tailored to the characteristics of the effluent being treated. This design allows for the absorption of daily loads of up to 3,000 kg of COD (Chemical Oxygen Demand) per day.

The anaerobic reactor design and the unique hydraulic regimes they feature provide two essential qualities of the Fluid-Anyole® system:

- Enhanced bacterial stability : the system exhibits strong resistance to changes in environmental parameters (such as input composition, operating temperature, and intermittent feeding).

- Effective treatment of a wide range of organic effluents : capable of handling both diluted and complex organic effluents, including those that are often impossible to treat with other processes. This includes composite effluents loaded with fats (such as whey, production waste) or suspended solids (like yeasts and phytopharmaceutical compounds).

Additionally, the system does not involve any moving parts or elements for mixing within the reactors. It requires only standard pumps and measuring instruments for operation, ensuring mechanical reliability. It’s a simple system, but not simplistic.

Key Performance Indicators

↘ of COD by more than 80%

↘ of TSS by 50%

Treatment capacity of

5 to 10 kg COD/m³ reactor per day

Biogas conversion between 0.28 and 0.35 Nm³ of CH4/kg of COD

We go the extra mile

Our skills are here to help you ; contact us for any questions or project ideas.

The diagnosis of your effluent potential is free.

Our realization at the Orval Abbey brewery-cheese factory

Anatis supported the industry from the preliminary study through to the operational monitoring of Fluid-Anyole.