Treat and valorize your cheese-making effluent

Your industry

Cheese dairies producing more than 500 tonnes/year of cheese or butter

Producing beer, softs or other foods? That's even better!

Your typical effluent :

Cheese or butter serum

Rinse water

Yeasts

Fluid-Anyole®, a solution for :

Complying with discharge standards

Empowering your serum

Controlling treatment costs and taxes

Reduce your water consumption

Responding to ESG constraints

The solution for treating and recovering your industrial effluent

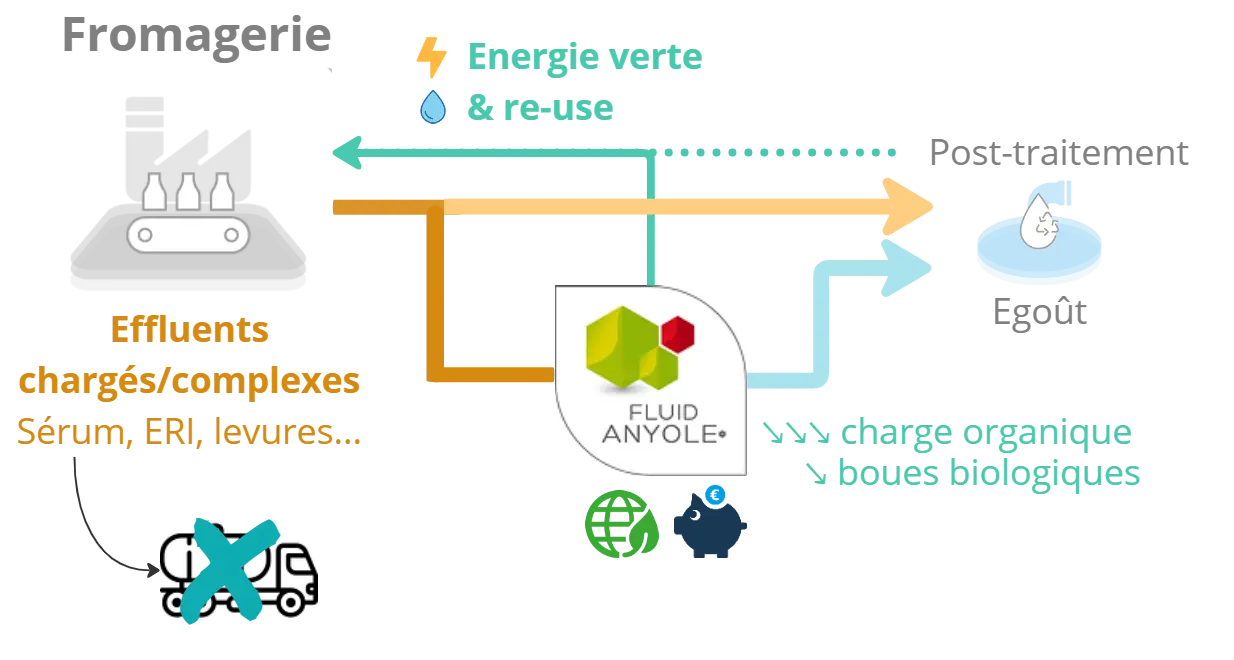

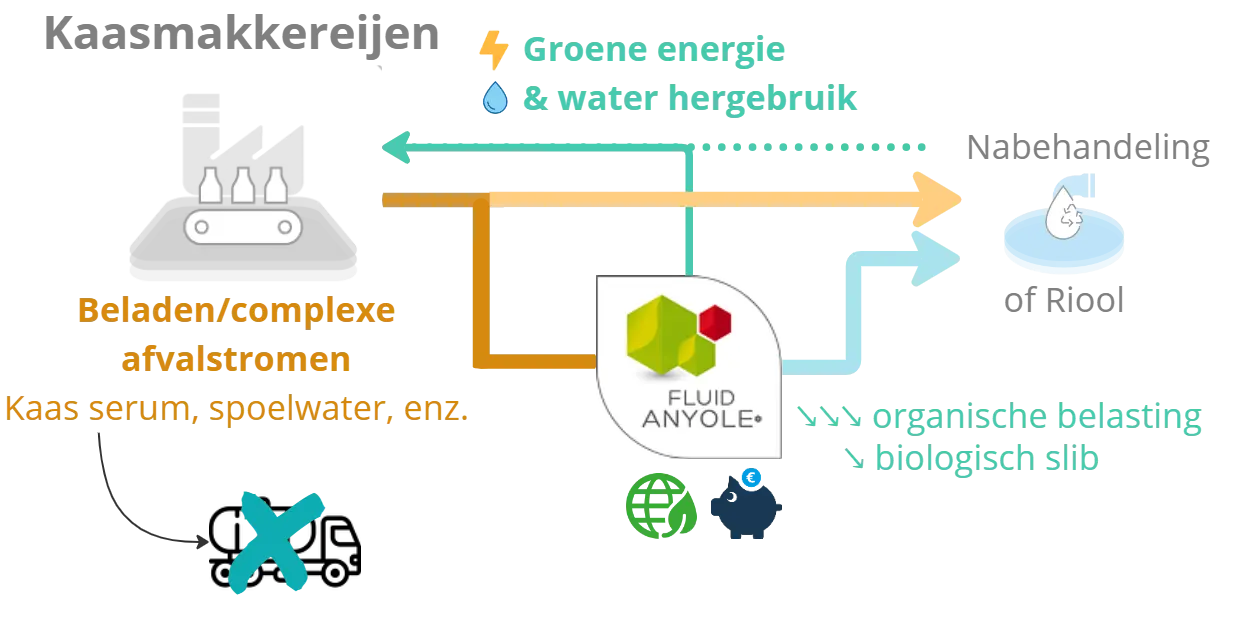

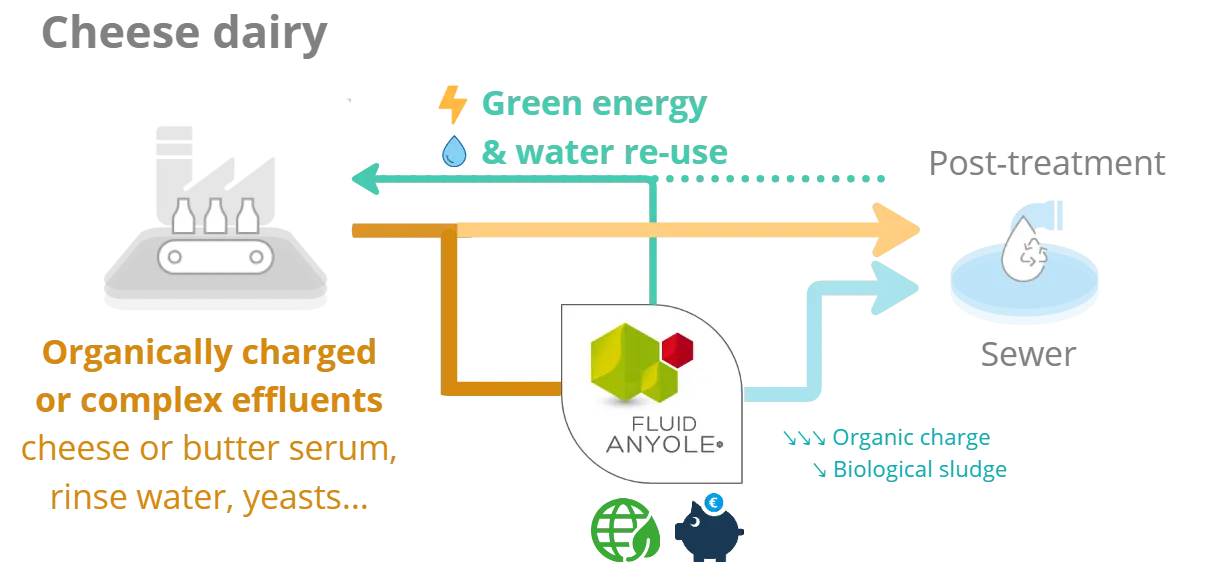

Based on the principle of bio-methanisation, the Fluid-Anyole® system naturally treats your organic liquid waste, offering you attractive savings and green energy production for your industry. Allowing you to move from a source of cost to a green and profitable treatment.

Adapted to your cheese dairy effluents

Whether on all or the most valuable part of your raw effluent: cheese or butter seruminse water (ERI), deactivated yeasts...

Tailor-made buried solution

Sized according to your needs and constraints, Fluid-Anyole® underground tank technology is installed in your industry, between the outlet of your liquid discharges and the return to the sewer or to your existing purification solution.

Automated, compact and mechanically simple in design, it offers high output stability and low operating costs.

Your effluent has potential

Let's talk about your project, the diagnosis is free.

Summary of your benefits

Sustainable Treatment

Natural process & limited land footprint

Compliance with discharge standards

Internalization of yeast and trub treatment (increased energy value ↗↗)

Improvement of the company's overall energy and carbon balance

Preparation for energy-autonomous reuse

Internal Valorization

Production of green electricity and heat

The energy from your effluents for your industry

Savings on internal and external treatments (e.g., elimination of trucks) and taxes

Positive ROI